Table of Contents

Introduction

In today’s competitive manufacturing and packaging industry, automation is key to improving productivity, reducing costs, and ensuring product consistency. The Bagging Machine plays a crucial role in packaging automation, widely adopted in printing, stationery, electronics, and gift packaging sectors.

Choosing the right Bagging Machine can significantly reduce labor, increase packaging speed, and ensure consistent quality. This guide will explain the working principles of Bagging Machines, their wide applications, PrintingMates product models, and practical selection guidelines.

How Bagging Machine Works?

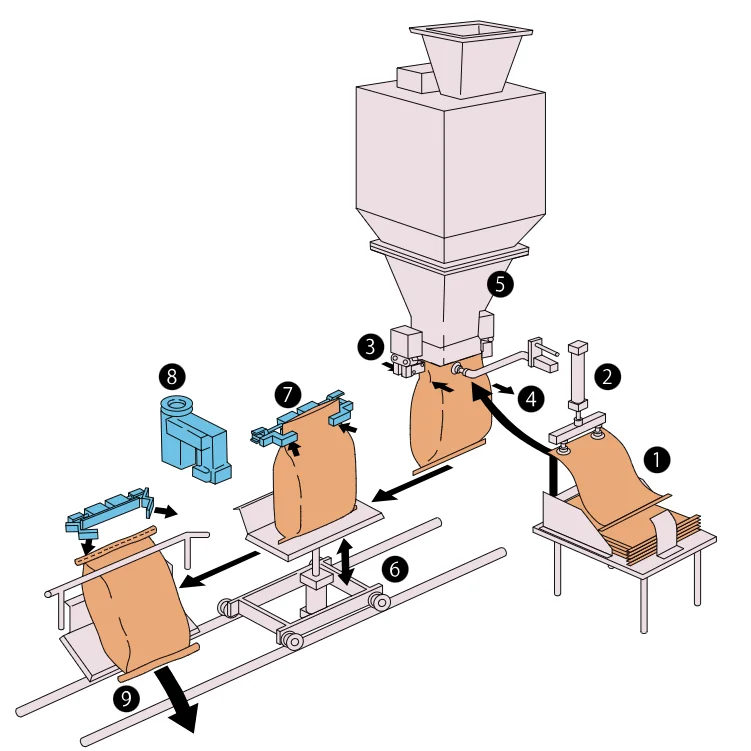

The Bagging Machine operates through fully automated steps including:

– Feeding: Automatically picking up products

– Counting: Accurately counting items per bag

– Folding: Folding manuals, certificates, or documents

– Bag Forming: Forming plastic film into bags

– Insertion: Inserting products into bags automatically

– Sealing & Cutting: Heat sealing and cutting finished bags

– Discharging: Automatically releasing packed products

Modern Bagging Machines utilize multi-axis servo motors and PLC motion control modules to ensure high-speed, high-precision, and highly stable operations, minimizing human intervention and reducing error rates.

Bagging Machine Applications

Bagging Machines are widely used for various flat or lightweight printed products, including:

– Instruction manuals for electronics, appliances, machinery

– Warranty cards, certificates, and authenticity labels

– Notebooks, exercise books, stationery packaging

– Greeting cards, red envelopes, holiday gift cards

– Anime booklets, collectible inserts, promotional materials

– Customized gift items, promotional giveaways

Automated bagging ensures professional, clean, and protective packaging that enhances product presentation and protects items during transportation.

PrintingMates Bagging Machine Product Line

Here, we’re proud to present three featured samples from our exhibition lineup—each one a reflection of QILI’s innovation in design, excellence in material selection, and precision in manufacturing craftsmanship:

1. FZ-120 Mini Automatic Bagging Machine

Features: Compact design for small-size products. Supports basic folding, counting, sealing, and fast switching.

Applications: Tags, cards, small manuals, jewelry inserts, membership cards, certificates.

2. FZ-240 Mid-Small Automatic Bagging Machine

Features: Versatile with integrated folding, trimming, stamping, labeling, adhesive labeling, sealing.

Applications: Manuals, certificates, envelopes, stationery, discs, greeting cards, gift inserts.

3. FZ-310 Mid-Large Automatic Bagging Machine

Features: Multi-axis servo control with PLC motion system for precise and stable large format packaging.

Applications: Books, magazines, catalogs, brochures, multi-book sets, large manuals.

4. FZ-320A Automatic Mid-high Bagging Machine

Features: Enhanced mid-high model optimized for higher output and long-time continuous operation. Ideal for production lines.

Applications: OEM bulk orders, batch packaging, customized inserts, large export orders.

5. FZ-520 Large Automatic Bagging Machine

Features: Flagship large-format model supporting oversized products. Fully upgraded servo system, perfect for premium packaging of oversized printed materials and gift sets.

Applications: Large manuals, oversized gift books, cultural packaging, and custom large-format inserts.

How to Choose the Right Bagging Machine?

When selecting a Bagging Machine, consider product size, packaging speed, production volume, functional needs, available space, and budget. Below are the recommendations:

Product Type | Recommended Model |

Micro-size products | FZ-120 |

Mid-small flat products | FZ-240 |

Mid-large booklets | FZ-310 |

High-volume continuous production | FZ-320A |

Large-format specialty packaging | FZ-520 |

Key Technical Features & Advantages

– Multi-axis servo system: high-speed and precise positioning

– PLC motion control: stable and efficient process

– Quick size memory switch: rapid model changeover

– Integrated folding, trimming, stamping, labeling functions

– Fully automated discharging system

– Smart interface: real-time monitoring, fault alerts, maintenance reminders

– Low maintenance cost: durable design for long-term stable operation

Conclusion

Bagging Machine plays a vital role in modern packaging automation. PrintingMates offers a complete series of Bagging Machines, delivering highly efficient, stable, and intelligent packaging solutions for global customers. For customized consultation and model selection, contact our technical team or AI customer support.