Table of Contents

Introduction: Sustainable Packaging as a Key Trend

In recent years, with the continuous improvement of environmental regulations and the rise in consumer awareness of sustainability, sustainable packaging has become a hot topic in the packaging industry. More and more companies are focusing on how to reduce packaging material waste, improve production efficiency, and meet the market’s demand for eco-friendly products.

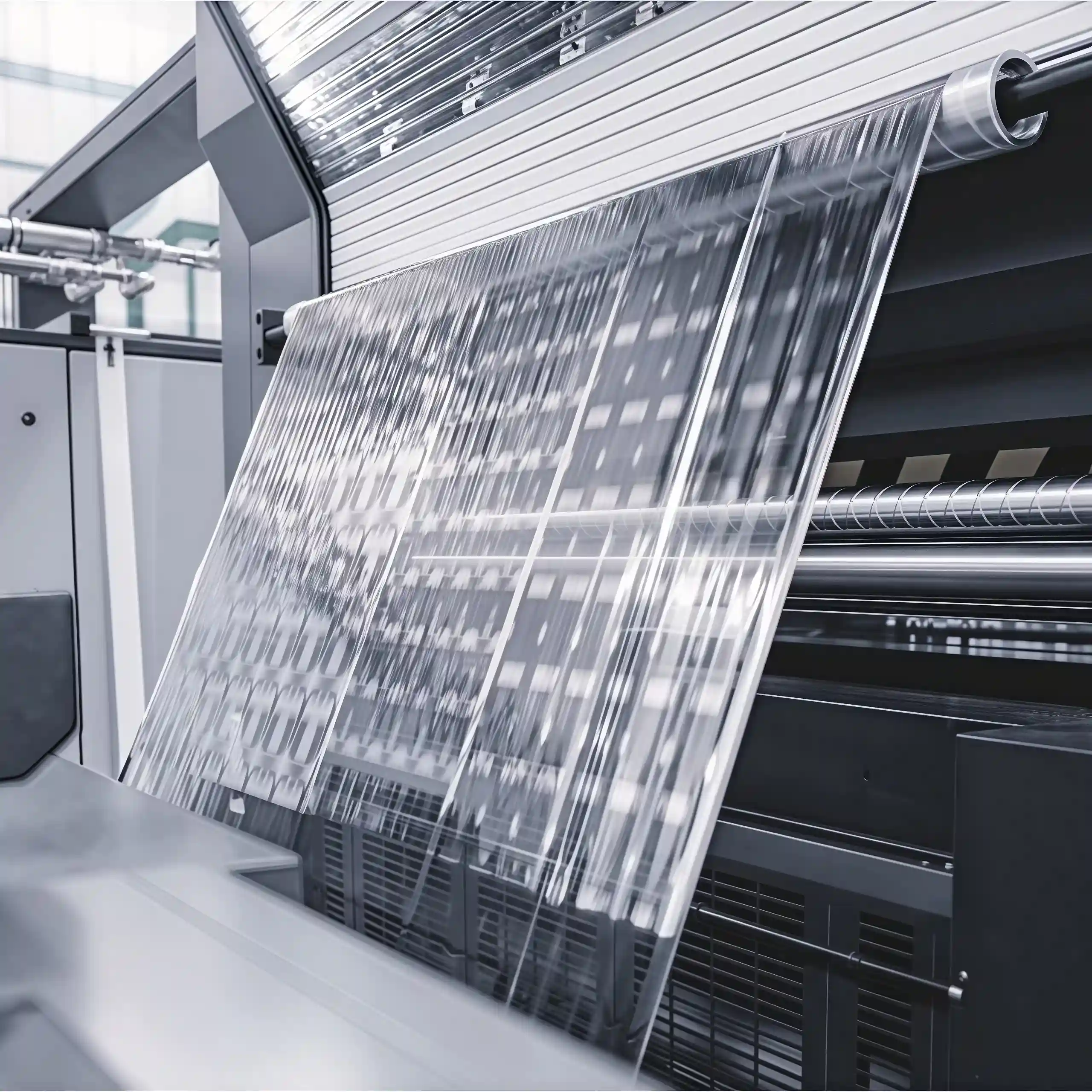

In this context, smart packaging equipment, with its precise control, efficient operation, and adaptability, has become a crucial tool in driving the sustainable transformation of the packaging industry.

Traditional Packaging Methods and Waste Issues: Paper and Plastic

Traditional packaging methods often rely on mass production, manual operations, and inefficient material usage. These methods not only lead to significant waste of raw materials but also increase energy consumption during the production process.

In the production of paper and plastic packaging, common waste issues include:

1. Inaccurate cutting of materials, leading to excessive waste

2. Frequent adjustments and material changeovers, resulting in losses

3. Overuse of packaging materials, contributing to resource waste

Smart packaging equipment, through precise control and automated production methods, effectively reduces these wastes and lowers energy consumption.

Environmental Advantages of Smart Packaging Equipment

Smart packaging equipment utilizes advanced control technologies, such as multi-axis servo systems and modular designs, to greatly improve material efficiency. These devices offer the following environmental advantages:

1. High-precision Cutting: By accurately positioning and cutting, material waste such as paper and plastic is minimized.

2. Reduced Defect Rate: Smart equipment can monitor every step of the production process in real-time, automatically adjusting parameters to avoid defective products.

3. Energy Savings: Through intelligent diagnostics and automated production, the equipment operates more efficiently, reducing energy consumption.

4. Use of Recyclable Materials: Some smart packaging equipment is designed to work with eco-friendly materials such as recyclable paper and plant-based plastics, further reducing environmental impact.

How Automation Reduces Waste in the Production Process

The automation of smart packaging equipment not only increases production efficiency but also plays a key role in reducing waste. Traditional manual operations and adjustments often lead to errors in production, generating significant waste. In contrast, smart equipment’s precise control systems adjust parameters in real-time, ensuring product quality in every batch. Here are some key features of smart equipment in reducing waste:

1. Automatic Adjustment and Monitoring: Equipment can monitor the production process in real-time, automatically adjusting cutting, folding, and packaging parameters to reduce errors.

2. Variable Data Support: In short-run and customized production, smart equipment can quickly switch between products while maintaining high precision, avoiding excessive adjustments and waste.

3. Process Optimization: Through data analysis, the equipment can automatically optimize the production flow, reducing unnecessary material waste.

Eco-friendly Materials in Packaging Machines

In the design of smart packaging equipment, more and more manufacturers are focusing on the adaptability to eco-friendly materials. By using recyclable paper, plant-based plastics, and biodegradable materials, smart packaging equipment can not only improve production efficiency but also help companies reduce their negative impact on the environment.

For example, some automation equipment can automatically adjust the production process based on the type of material being used, maximizing material utilization and reducing waste. At the same time, smart packaging equipment can support the use of various eco-friendly materials, including FSC-certified paper and recyclable PET materials, promoting green development in the packaging industry.

How PrintingMates Helps Customers Achieve Sustainable Packaging

In the design of smart packaging equipment, more and more manufacturers are focusing on the adaptability to eco-friendly materials. By using recyclable paper, plant-based plastics, and biodegradable materials, smart packaging equipment can not only improve production efficiency but also help companies reduce their negative impact on the environment.

For example, some automation equipment can automatically adjust the production process based on the type of material being used, maximizing material utilization and reducing waste. At the same time, smart packaging equipment can support the use of various eco-friendly materials, including FSC-certified paper and recyclable PET materials, promoting green development in the packaging industry.

Conclusion: Driving the Green Future of the Packaging Industry

Smart packaging equipment has brought revolutionary changes to the packaging industry, especially in terms of environmental protection and efficiency. By combining automation, intelligent control, and eco-friendly materials, smart packaging reduces production waste and optimizes resource use throughout the entire production chain. PrintingMates will continue to lead the development of smart packaging technology and provide global customers with sustainable packaging solutions.