Table of Contents

What is Cold Foil Printing?

Cold foil printing is a modern inline technique where metallic foil is applied using UV-curable adhesive and a printing plate. It is conducted directly on the printing press without heat or custom dies, allowing high-speed production with fewer setup steps. Cold foil printing is particularly suited for applications requiring variable data, short runs, and rapid delivery, offering flexibility and cost efficiency, especially in commercial packaging and labels.

What is Hot Foil Stamping?

Hot foil stamping is a traditional process that uses a heated metal die to transfer foil onto the surface of the substrate. It requires custom tooling and heat, making it effective for luxury applications such as wine labels, hardcover boxes, greeting cards, and invitation materials. The advantages lie in its deep embossing effect and ability to work on textured surfaces, though it comes with higher costs and longer preparation times.

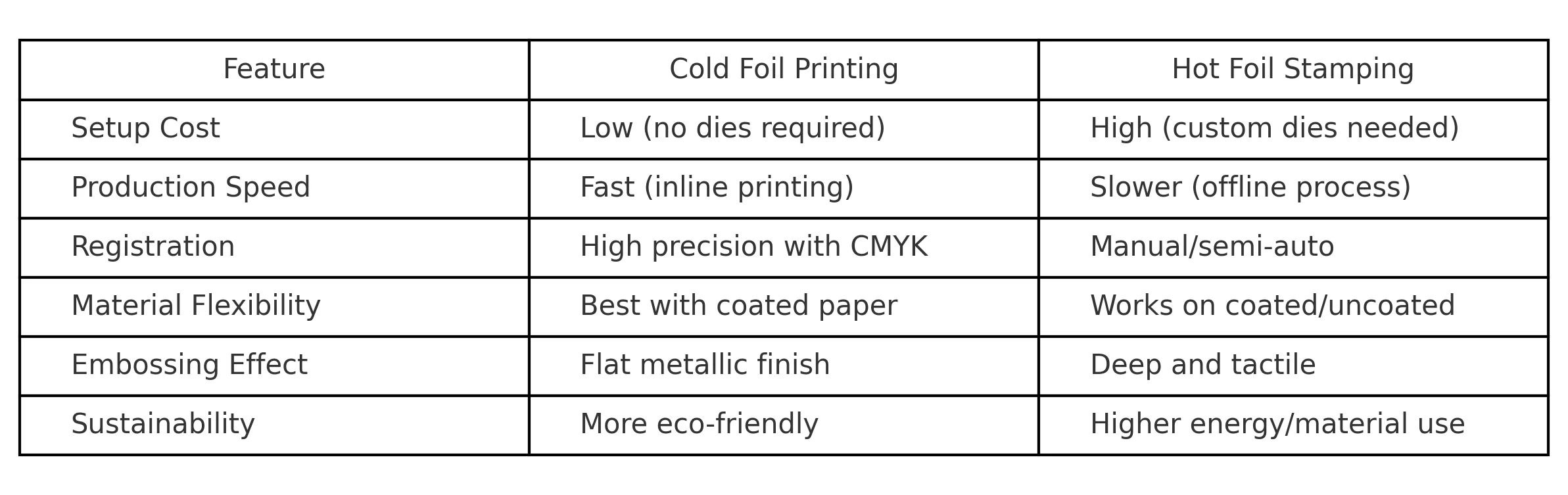

Comparison Table: Cold Foil vs Hot Foil

Packaging Applications: Which Is Better?

Hot foil is best for premium, tactile packaging such as rigid boxes, specialty cards, and high-end labels. Cold foil excels in fast-moving goods, cosmetic boxes, folding cartons, and any scenario requiring fast turnaround or short-run customization. Cold foil’s ability to be printed inline with CMYK or spot colors makes it suitable for modern, high-speed, high-flexibility workflows.

Why Cold Foil Printing Is Becoming the Preferred Choice

– No need for metal dies = lower upfront cost

– Inline printing = faster job turnaround

– Short-run friendly: variable data & design flexibility

– Lower energy consumption and reduced foil waste

– Compatible with hybrid/digital presses

These benefits align with today’s packaging needs, where brands are looking for faster customization, greener processes, and cost-effective metallic enhancement.

Cold Foil Printing Equipment from PrintingMates: LeapFoiler

Our flagship machine – LeapFoiler Offset Cold Press Machine II Pro – brings high-performance cold foil transfer to your offset press. Key features include:

– Model: CFU-1020 II PRO

– Foil width: 100–970mm

– Foil thickness: Supports 6μm

– Material: PET

– Speed: Up to 12000 sheets/hour (continuous)

– Operation: Supports both continuous & step foil skipping

– Multi-roll: 2–5 foil rolls simultaneously

– Skipping Mode: Vacuum pressure tension + dual servo control

– Changeover: No long airshaft needed, supports fast switching

– Power: 15KW

– Pneumatic: 0.6Mpa 1.5m³/min

The LeapFoiler combines advanced automation, energy efficiency, and precision, ideal for high-speed offset production environments.

Conclusion

Cold foil printing is a fast, flexible, and environmentally friendlier alternative to traditional hot stamping. For packaging companies looking to combine visual appeal with production efficiency, it is the superior long-term investment. Contact PrintingMates to explore how cold foil can transform your print line.